How Does a Declutchable Gear Operator Work?

A declutch gear operator, also known as a declutch-able manual override or a manual handwheel, is a device commonly used with industrial valves and actuators to manually operate the valve when needed, regardless of the automated or electric control system. It provides a means for manual operation in case of power failure or when maintenance or troubleshooting is required, without removing the actuator.

Here’s a general description of how a declutch gear operator works:

- Normal Operation (Clutch Disengaged):

- In the normal operating mode, the gear operator is “declutched” or disengaged from the actuator and valve drive train, allowing the actuator to freely move the valve without interference.

- The automated control system or electric motor drives the actuator, and the declutch gear remains in a disengaged state.

- Manual Operation (Clutch Engaged):

- When manual operation is necessary, such as during power outages or system maintenance, the actuator must first be disconnected from the power source to prevent unwanted accidental operation.

- Next, the operator engages the clutch mechanism. This engagement allows the gear override to engage the actuator and valve drive train and operate the valve open or closed.

- Resume Normal Operation (Clutch Disengaged):

- After manual operation is complete, the operator disengages the clutch mechanism to disconnect from the actuator and valve drive train.

- After disengagement, the actuator can be reconnected to the power source for normal automated function.

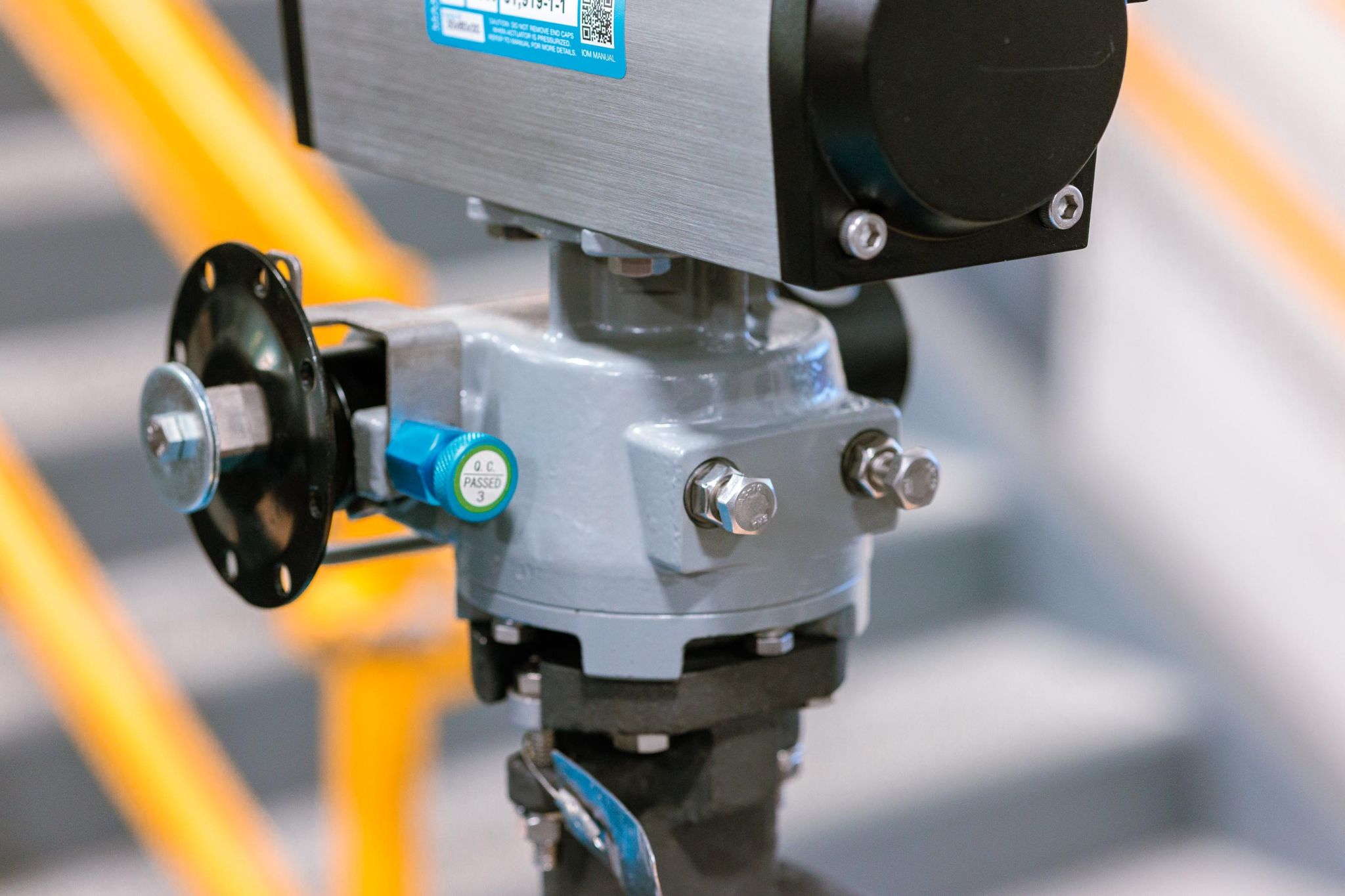

The images show our Declutchable Gear Operator

and details the Block & Bleed feature.

Max-Air Technology is here to support your flow control needs. If you need override, failsafe solutions, etc., we have you covered!