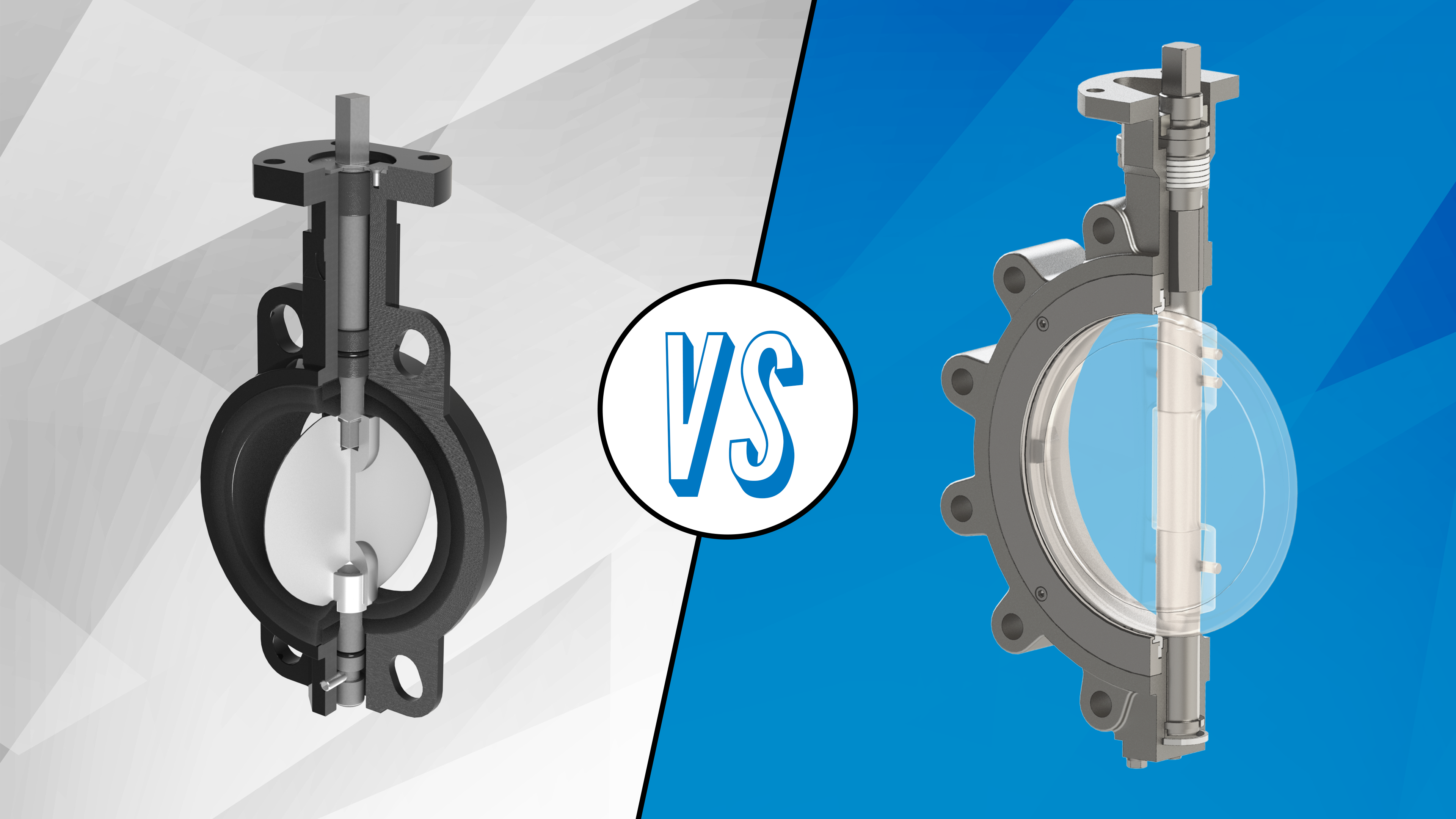

What is the Difference Between a Resilient Seated Butterfly Valve & High Performance (Double Offset) Butterfly Valve?

Both resilient seat butterfly valves and double offset high-performance butterfly valves are used in various industries for controlling the flow of fluids. However, they have distinct design features and applications that set them apart. Let’s explore the key differences:

1. Seating Design:

- Resilient Seat Butterfly Valve: This type of valve has a soft, elastomeric (resilient) seat material, typically made of materials like EPDM or Nitrile. The resilient seat provides a bubble tight seal and zero leakage.

- Double Offset High-Performance Butterfly Valve: The double offset design refers to the two different offsets present in the valve – the first offset is in the shaft, and the second offset is in the disc. The double offset design enhances sealing performance and reduces wear, providing a tight shut-off even in high-pressure and high-temperature applications. A wide range of seat materials are available such as soft seats, firesafe seats, and full metal seats, each designed for specific applications and shutoff requirements.

2. Performance and Pressure Rating:

- Resilient Seat Butterfly Valve: Resilient seat valves are commonly used in low to moderate pressure and temperature applications where a tight seal is necessary. They are suitable for applications where cost is a significant consideration.

- Double Offset High-Performance Butterfly Valve: These valves are designed for high-pressure and high-temperature applications. The double offset design allows for better performance under challenging conditions, making them suitable for industries such as oil and gas, petrochemical, and power generation.

3. Applications:

- Resilient Seat Butterfly Valve: Typically used in water treatment, HVAC systems, and other applications where moderate pressure and temperature conditions are present. They are cost-effective and provide reliable performance in less demanding environments.

- Double Offset High-Performance Butterfly Valve: Suited for applications where higher pressure and temperature conditions are encountered, such as in chemical processing, power generation, and industrial processes.

4. Construction Materials:

- Resilient Seat Butterfly Valve: Generally constructed with materials such as ductile iron or cast iron with a corrosion-resistant coating. The disc and stem may also be coated for added protection.

- Double Offset High-Performance Butterfly Valve: Materials for construction may include stainless steel, alloy steel, or other high-performance materials, providing better resistance to corrosive environments and higher temperatures.

In summary, the choice between a resilient seat butterfly valve and a double offset high-performance butterfly valve depends on the specific requirements of the application, including pressure, temperature, and the desired level of performance and reliability.

Resilient Seated

High Performance

(Double Offset)

Max-Air Technology is here to support

your flow control needs.