How Does a 4-20mA Electro-Pneumatic Positioner Work?

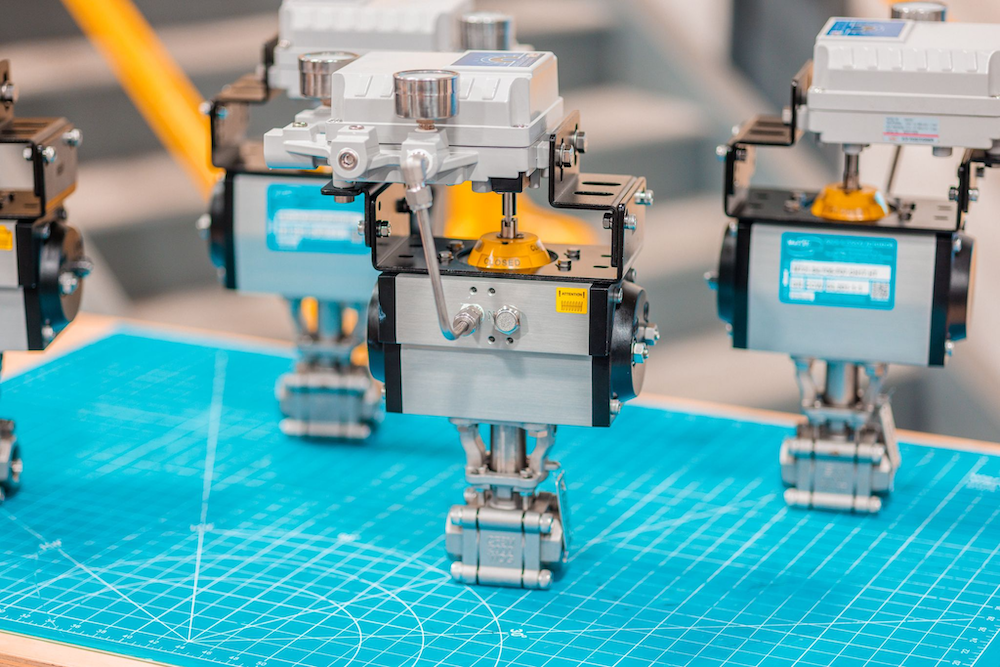

A 4-20mA electro-pneumatic positioner is a device used in industrial automation to control the position of a valve operated by a pneumatic actuator. The 4-20mA designation refers to the current loop signal used to communicate between the positioner and the control system.

Here’s how a 4-20mA electro-pneumatic positioner typically works:

- Control Signal (4-20mA): The positioner receives a 4-20mA current signal from the control system. This current signal represents the desired position or setpoint of the valve. The range of 4mA to 20mA is proportional to the range of motion of the valve, where 4mA corresponds to the minimum position, and 20mA corresponds to the maximum position.

- Feedback Mechanism: The positioner continuously monitors the actual position of the valve through a feedback mechanism. This feedback could be provided by a position sensor, such as a potentiometer or an encoder, which measures the current position of the valve.

- Comparison and Error Signal: The positioner then compares the desired position (setpoint) received from the control system with the actual position feedback. The difference between the desired and actual positions is the error signal.

- Control Logic: The positioner uses control logic to determine the appropriate action needed to minimize the error. If the actual position is less than the desired position, the positioner will increase the valve position. If the actual position is greater than the desired position, it will decrease the position.

- Actuator Adjustment: The positioner adjusts the valve position by changing the air pressure supply to the actuator, causing the actuator to move towards the setpoint. This adjustment brings the actual position closer to the desired position.

- Continuous Loop: The process of receiving the setpoint, comparing it with the actual position, making adjustments, and providing feedback is continuous. The positioner operates in a closed-loop system to maintain the desired position as accurately as possible.

The 4-20mA current loop is commonly used in industrial settings because it is less susceptible to electrical interference and allows for long-distance transmission of signals without significant signal degradation. This makes it a reliable method for precise control in industrial automation applications.

Max-Air Technology is here to

support your flow control needs.