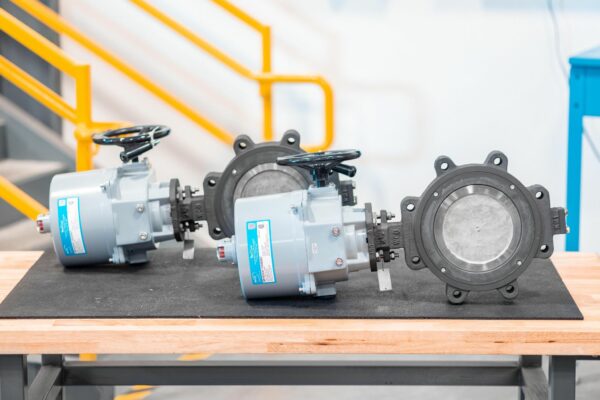

Mission Critical Data Center Valves

Max-Air Technology partners with Mission Critical Facility Engineers,

Max-Air Technology produces reliable valve products,

dependable fail-safe & overrides, and innovative flow efficiency designs.

Valves for Data Centers

KEEPING YOUR DATA CENTER COOL

CAN BE A MAJOR EXPENSE—AND

FAILURES CAN BE COSTLY.

Max-Air Technology is committed to providing reliable valve solutions for mission-critical Tier 4 data centers across the United States & Canada.

At Max-Air Technology, we understand how crucial uptime and efficiency are for data centers. Our specialized range of valves is engineered to support the demanding needs of modern facilities, ensuring peak performance in cooling systems.

Every data center is unique, and Max-Air Technology is dedicated to offering tailored solutions that fit your specific project requirements. Whether you’re building a new facility or upgrading your current operations, our team is ready to partner with you to ensure you get the right valve solutions for long-term success.

Cooling Tower & Chiller Valves

In Stock in USA & Canada

NSF – Approvals

050/051 & 650/651 Series

Resilient Seated

- 1.5” – 48” Ductile Iron Body

- Stainless Steel Body Butterfly Valve; sizes 2” – 24”

- Wafer and Lugged Body Styles Available

- Max-Pressure 200 PSI Double Dead-End Service

- Malleable Iron Handles Available

- Cast Iron Gear Operators Available

- ISO 5211 Automation Ready Design

- Cost Competitive & Well Stocked

- 3-Year Standard Warranty

Sales Literature

Data Sheets

Submittal Drawings

High CV Slim Disc Design

Our Slim Disc Design offers up to 12% increase in flow on sizes 2”-12”.

This efficiency provides an incredible cost savings when used in cooling purposes.

Open

High CV Slim Disc Design vs.

Standard Through Stem Design

Closed

High CV Slim Disc Design vs.

Standard Through Stem Design

A compounding difference in flow!

In Stock in USA & Canada

CE, PED, CRN

250/251 Series

Resilient Seated

-

Industry Leading 3-Year Limited Warranty

-

250 Series Wafer Ductile Iron Body sizes 2” – 24”

-

251 Series Lug Ductile Iron Body sizes 2” – 24”

-

Bi-Directional Shutoff 250 PSI

-

Bi-Directional Dead End Service 250 PSI (Lug only)

-

Install between Standard ANSI class 125/150 flanges

-

250 Series Wafer also compatible with PN10/PN16 flanges

-

ISO 5211 square drive shaft for optional automation

-

Conforms to MSS-SP-67, MSS-SP-25, API 609

-

Designed for blowout-proof service

-

Permanent Integral Seat Design

-

Vacuum service capable (Please consult factory)

In Stock in USA & Canada

800 Series | Double Offset

High Performance

(Series 850, 851, 852, 853, 860, 861, 862, 863, 871)

- ANSI 150, 300, & 600 in all styles

- Wafer, Lugged, & Flanged styles

- WCB & CF8M bodies stocked

(A broad selection of other materials available) - Blow out proof stem design

- Stainless Steel disc & stem standard on stocked trims

- TFM 1600 seats are standard, other soft seats are available

- Fire Safe & Metal seated versions are available

- ISO 5211 mounting is standard. (Direct mount for 12” & smaller, w/ included bracket on larger size)

- Class VI / bubble tight bi-directional sealing on all soft seated trims

- Dead End service to full pressure rating in preferred direction

- Control trim w/ anti-noise & anti-cavitation features available

Sales Literature

Submittal Drawings

IOM Manual

High Visibility

Beacon Options

Reflective Surface, Arrow End Caps,

& Low Profile Offset

Reflective Paint for

Low Light Conditions

(Retrofit Options Available for Most Manufacturers.)

Need information on how to get our products? Send us an inquiry!